When I first started hearing about 3D printing, I couldn't comprehend how it could work. Earlier this year, I read an article about a house built using a giant 3-D printer which further blew my mind. The concept is finally making more sense after hearing Larry Doerr ’01 M.B.A., COO and EVP of North America for Stratasys, at a recent Opus College of Business Master's Pub.

Here are the basics:

3D printing isn’t exactly like using a run of the mill desktop printer.

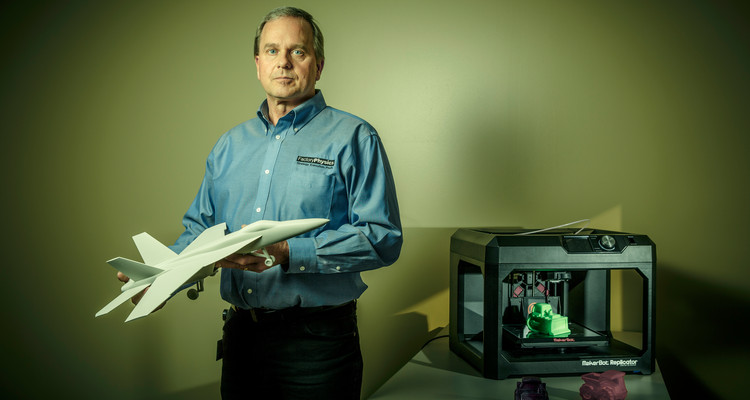

There are several different brands of 3D printers in the market. Stratasys owned brand MakerBot is a market leader in these printers with models that vary in size. The smallest is similar in size but not in function to your home printer/scanner. However, it costs around $1299 with materials cost around $28 for 50-100 parts.

How does it work?

The technology is all about layers. The first step is to obtain CAD drawings for the product you’d like to print. Don’t know how to create CAD drawings? According to Mr. Doerr, the “Thingiverse” is an online portal similar to iTunes with 600K downloadable CAD files. Want it customized? Asking for your customization within the Thingiverse community of 3 million developers would likely lead to a customized CAD drawing within a short amount of time, for free.

Once you have the CAD drawing, the printer will splice it into layers. These layers are each printed individually and connected to each other to create a final product. The largest layers can be 3ft x 2ft x 3ft. These pieces are put together a product as big as a car bumper or hood.

You likely used a product from a 3D printer before noon today.

3D printing technology has been available since 1988 but awareness was low until recently. It is currently being used in the following industries; architecture, medical, industrial, aerospace, automotive, military, consumer, dental, jewelry and education. From the plastic on your iPad to dental modes, car parts to spaceship components, there are 3-D printed products everywhere. Part of the reason for the adoption of 3D printed products is the strength to weight ratios. They are light in weight but very strong.

Other 3-D Printing Fun Facts:

- Normal, a company out of New York, makes 3D printed earbuds that are customized to the structure of your ear.

- Lockhead Martin used 3D printers to make a telescope and airplane wings.

- GE is one of the biggest users of 3D printing but was one of the latest adopters of the technology.

- Stratasys began as an entrepreneurial start-up but now employs three thousand employees. They’ve grown 25-30% the last few years. Read more about Stratasys in B. magazine.

- A 3D printer was used to help a doctor reconstruct a shattered knee. Using an MRI, a replica of the bad knee was created for the doctor before the first cut into the knee. This aided in creating a more effective surgical plan.

Want to see a 3D printer in use? Check out how this company made a skateboard: