Activity on the St. Thomas campuses have slowed down in response to the coronavirus, but thanks to the efforts of more than a dozen St. Thomas engineering, education and chemistry students, the university’s 3D printers are not sitting idle: They’re turning out personal protective equipment (PPE) to support the Twin Cities medical community.

Senior mechanical engineering major Collin Goldbach kicked off the process after spending time with his grandparents during spring break last month, wondering

Reusable respirators created by St. Thomas students.

at the time what more he could do to help the ongoing fight against the coronavirus pandemic. A callout on Snapchat asking peers if anyone wanted to help him do some good prompted more than a dozen responses in the first hour, which has led to several printers on campus now turning out face shields destined for local hospitals.

“I recently applied to graduate school, and on all of my cover letters I said that I’m a person who believes if you have an opportunity to help, you have a duty to,”

Goldbach said. “If everyone steps up who can, this becomes a lot less stressful for people who are needing to face this problem.”

Goldbach and his peers have certainly stepped up, drawing on designs for the face shields from St. Cloud State University to streamline the input process and get St. Thomas’ machines producing. Students sourced 3D printers from faculty and programs across the engineering department and fixed two broken machines; with all fully operating there’s capacity for 60-70 face shields per week.

“Our students are really living out the mission of St. Thomas and working to make ‘all for the common good’ a reality in this time,” said School of Engineering Professor John Wentz, who donated his machine to the effort as well. “Their organization and ensuring that they’re working with appropriate groups to really provide the right support where necessary has been very impressive.”

Expanding the impact

Students have divided up work between operating the machines in the Facilities and Design Center (FDC) and communicating with local hospitals about what they need most.

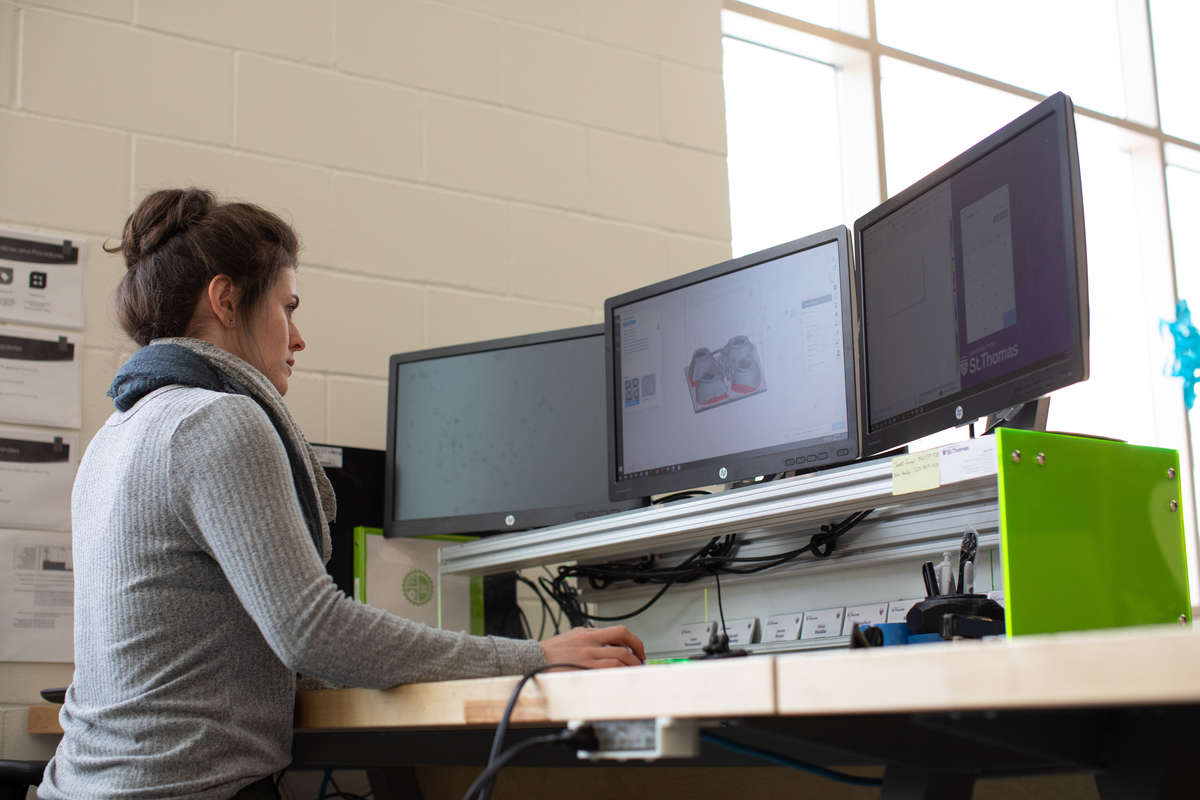

Erin Westman works with 3D printing software.

“Our greatest challenge was in determining how we could be of the greatest service to these medical professionals. From the beginning, we’ve had the high-quality manufacturing equipment needed to produce PPE, but we couldn’t put those resources into use until we identified the problem that troubled them the most,” said sophomore Erin Westman. “In class, my engineering professors frequently stress the importance of developing our interpersonal communication and problem-solving skills. Now I understand why, because without them, we never could have devised an appropriate solution and then delivered it into the hands of those in need.”

Students are also working to prototype designs for respirators, and senior chemistry major Katie Breuckman has been coordinating with

Chemistry major Katie Breuckman cleans up headbands that will be used for face shields.

hospital contacts to help ensure the department is available to contribute disinfectant solutions as needed.

“Contributing to this effort is incredibly important for reducing the impact of COVID-19 on our health care system. We need our health care workers to be protected from the virus while they help to save those who

have it,” Breuckman said. “PPE is a basic necessity that every health care worker and anyone who may be exposing themselves to the virus to carry out essential work should have access to.”

“It was tough to sit back and do nothing while reading stories of the sacrifices medical employees were making,” said engineering major Isaac Fennewald, who has been helping operation machines in FDC. “When Collin came along with this idea, it was a no-brainer to hop on board.”