Each year, the Engineering Senior Design Clinic immerses students in hands-on design and engineering problems in collaboration with local industry. This two-semester course is a critical component of the St. Thomas engineering curriculum as it requires student teams to engage with real-world design problems and to experience the complete engineering design cycle.

The first semester focuses on defining customer requirements, thoroughly researching the problem and evaluating potential design solutions. During the second semester, teams apply engineering principles to refine the design and construct operational prototypes. Graduating seniors then display their work at a formal design show.

This year's Senior Design Clinic Show will take place Friday, May 5, from 2:30-5 p.m. in Scooter's in the Anderson Student Center.

The St. Thomas Senior Design Clinic is a unique educational experience for these young engineers. Projects are selected to span a broad range of student interests, from product design for global sustainability and peace engineering to manufacturing optimization of medical devices. Teams of three to five students undertake each project, with a mix of electrical, mechanical and computer engineering students appropriate for the project content. The interdisciplinary nature of the teams differs from many other universities that have senior design project programs and is an exceptional opportunity for students to experience how multidisciplinary teams collaboratively solve problems in the real world.

One of the most valuable lessons students learn is how to tackle problems that do not have obvious solutions. Unlike textbook questions, which often have a single correct approach and solution, real-world problems possess a high degree of ambiguity. Students must brainstorm potential solutions and apply engineering rigor and sound judgment to select a solution that will best fulfill the unique design parameters for their projects.

Other critical job-related skills that students hone in Senior Design Clinic include project management and professional communication; these skills are necessary for the students to create milestones appropriate for a successful project completion and then communicate that solution in a professional manner to their sponsoring companies.

The Senior Design Clinic industry partnerships provide invaluable networking opportunities for St. Thomas students. Creating connections with local professionals through projects frequently leads to patent disclosures, recommendations and job offers. In addition, many of the industry sponsors are St. Thomas alumni, attesting to the strength of the alumni network and support they provide engineering students.

Senior Design: Improving Airflow Rates for 3M Respirators

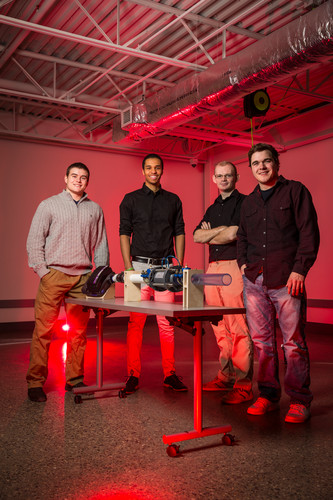

From the left, Nathan Osborne (mechanical engineering), Samuel Vilone (electrical engineering), Ben Waterfield (mechanical engineering) and Cody Merrell (mechanical engineering) worked on a flowmeter with 3M for their Senior Design team project.

One Senior Design team worked with 3M, a multinational corporation headquartered in Minnesota with $30 billion in annual revenue. 3M manufactures a wide array of products for health care, safety, electronics and consumer marketplaces.

The 3M Personal Safety Division designs and manufactures equipment for respiratory, hearing and eye protection. One of those products, the Powered Air Purifying Respirator, provides filtered air for personnel working in areas with high concentrations of chemicals or dust. These devices require testing to ensure they achieve the flow rates required by government and customer regulations. Current laboratory flowmeters used for product testing require a pre-filter, creating significant pressure drops that must then be remedied by another complex system.

The St. Thomas team is designing a prototype with an accurate flowmeter with negligible pressure drop to allow direct insertion into the airflow without creating backpressure.

Senior Design: Teaching a Pentair Robot to Work With Humans

Pentair, an industrial company focused on water, fluid and thermal controls, requested that our Senior Design students use a collaborative robot to improve the efficiency in the manufacture of electric heaters.

A Minnesota company, Pentair employs more than 30,000 globally. The Technical Solutions Division designs, manufactures and services heat-management solutions that provide thermal protection to temperature-sensitive fluid and electrical system applications.

The St. Thomas team is working to integrate the robot into an existing manufacturing process flow as well as design a portable base for mounting the robot. The robot will pick and place parts and interact with human operators and industrial equipment in a safe and reliable manner.

The School of Engineering always is searching for new industries and problems to be solved with our Senior Design Clinic. If you are interested in learning more about how your company can get involved, contact us at (651) 962-5750 or engineering@stthomas.edu.