Students with innovative engineering ideas participate in St. Thomas’ Senior Design Clinic each year. Four of those former students now are listed as inventors on a U.S. patent issued in August.

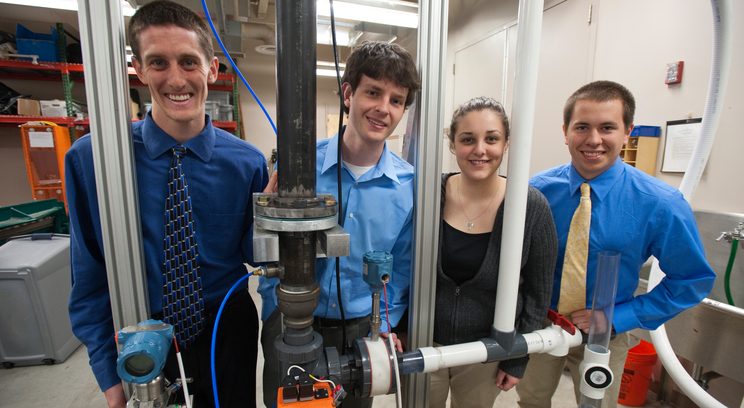

Kelli Lais, Morgan Impola, Isaac Remer and Brian Sames developed a multiphase flowmeter for their 2010 Senior Design Clinic. The two-semester course pairs senior engineering majors with companies to develop prototype solutions to real-world problems. A fifth inventor listed on the patent is Roger Pihlaja, the group’s industry contact for their company collaborator, Emerson Process Management Rosemount Division.

Although St. Thomas allows companies to retain all intellectual property generated by students in the design clinic, meaning Emerson will retain control of the flowmeter, Impola was happy to receive the patent.

“It’s pretty exciting. I’d definitely put it up there with one of the best academic accomplishments that I put on my resume,” said Impola, who works at Xcel Energy. Lais is employed at General Dynamics and is a UST MBA student. Remer works at Minco, and Sames is with Emerson Process Management.

Though the project-to-patent lag of three years seems long, Don Weinkauf, Ph.D., dean of engineering, said this wait period is average and is to be expected of a long and sometimes complicated process. “It may take a few years for the patent to get issued, depending upon the priorities of the company for that particular thing and what the patent’s office is capable of processing. That’s why you always see ‘patent pending.’”

“There’s a whole strategy to filing a patent that involves marketing. Some people want to get a patent so they can license the technology to somebody else, some companies want to get a patent so their customers can use it,” Weinkauf explained.

So what does a flowmeter do?

There are more than 500,000 oil wells in the United States with 156,000 alone in Texas. According to Weinkauf, an oil well, later in its life, begins producing a “frothy mess” of significantly larger distributions of water, oil and natural gas. Since knowing what is flowing from the wellhead is a large part of determining the economics of a well, flowmeters are used to measure the liquid flow; however, the market price of such a convenience hovers around $100,000 – a big capital investment for an oil well.

Emerson presented the students with the challenge of creating a low-cost, three-phase flowmeter capable of measuring the amount of each substance, and the students stepped up to the challenge.

“It was easy to tell [our project] was going to be applicable to a bigger industry, and that was appealing,” Impola said. He and Sames, the electrical engineers on the project, programmed valves that could obtain fluid samples and collected data from sensors needed to perform measurements on the three substances, while Lais and Remer, mechanical engineers, ran tests to simulate fluid flow and built the hardware for the prototype.

The team, sans Impola, visited an oil well in North Dakota in January 2010 to assist in the process. “We had a couple of concepts planned and after going out to North Dakota, we were able to cross some things off,” Impola said. “It was really helpful for our team to be able to travel and see where this kind of product would be used.”

In the end, the students built a system that measures fluid flow through an elaborate process: On request, it can grab a sample of the three-substance mixture, trap it in a long-standing column and wait until the gas rises to the top and the oil floats to the top of the water. With guided wave radar, the students could detect where a change in dielectric constant occurs after natural settling is complete and used this information to determine the distance between each of the surfaces – gas to oil and oil to water – and calculate the amount of oil, water and natural gas in the sample. With the cost of their prototype approximately $10,000, the project was a success.

Future of the flowmeter

According to Weinkauf, the result of not requiring companies to share the intellectual property generated in the design clinic has been a strong interest for the company to bring forward more authentic projects. “If there was ever a chance that they’d have to share, why would they want to participate in the clinic? We get a lot of participation from companies that wouldn’t normally work with a university because they might have to lose or share that intellectual property.”

Pihlaja thinks the patented flowmeter is “a very good deal” for Emerson. Emerson derives half of its sales in oil and gas production, and this product fits nicely into in a large portfolio of products the company sells into the industry.

The patent was a critical milestone in the development of the product, serving as a foundation that lays out the basic principles by which the instrument operates, but the flowmeter is not yet ready for a commercial launch. “If you think about when you introduce a new product, there’s a portfolio of intellectual property that usually goes with it. As the instrument is commercialized, I’m sure there will be other intellectual property that’s developed around it,” Pihlaja said.

A success for St. Thomas

The senior design clinic has 25 projects this year, which is about average. Weinkauf estimates that four or five invention disclosures are entered per year. Since the relationship exists largely between the students and the company, the university doesn’t require companies to come back and report patent information, but Weinkauf is hopeful for the future. “My guess is that we’ll start to see around one patent a year, with the three-year time lag, that actually is executed.”

Weinkauf, Impola and Pihlaja all agree the Emerson patent shows the high level of engineering in the design clinic.

“Emerson did a good job of coming forward with a good project and letting students get a chance to do something that’s not just a small project they have sitting on the back burner, but something that they can use with students’ hard work and effort researching,” Impola said. “Hopefully it’ll encourage companies to see that St. Thomas students were able to get a patent and say, ‘Let’s give them something difficult that we want to research and hopefully they can follow through as well.’”

And for the former students themselves, it’s “a feather in their caps,” Weinkauf said. “It’s an excellent experience because they’ve had to interact with attorneys, talk about claims, learn about how to protect intellectual property. It’s something they can always say for themselves: that they walked into a problem space, learned what was important and created something new, and I think that’s what engineering is.”