If you’re at all like me, 3-dimensional printing is something that you understand in principle only. The general gist is pretty easy to grasp (you can use computers and an actual printer to make 3-D objects), but the nuts and bolts of that process are pretty foreign.

Luckily for me (and you, if you read the rest of this), there are professors and students at St. Thomas who have been working with 3-D printers for years. They were more than happy to give a crash course on how they make objects from their imaginations go to objects in their hands.

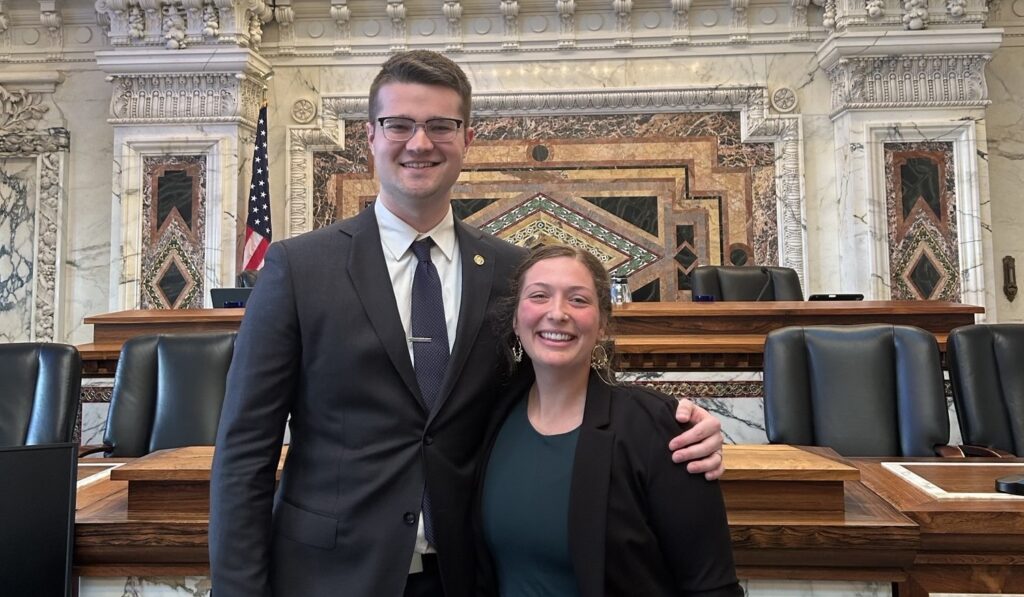

“It sounds hard,” junior Lindsey Bollig said. “It’s not that complicated once you know how to do it.”

Take that with just a small grain of salt: Bollig designed and made her 3-D printer from scratch. By printing parts from classmate Austin Otto’s 3-D printer. That he made from scratch.

Before diving into the how, a quick history: 3-D printing has been around for a few decades, and St. Thomas’ work with them goes back to the 2007-08 school year. It was then the school purchased a zCorp 3-D printer. Since then, engineering classes have been using the printers to build prototypes and conduct research.

Professor Brittany Nelson-Cheeseman pointed out that because 3-D printing was more of a niche field until recently, there are plenty of research opportunities for students to contribute to the emerging science. For the most part professors and students use smaller-scale, custom-made 3-D printers for research projects, and the school’s purchased printers to create larger-scale objects and prototypes.

While there is plenty of variation in size, speed and consistency across the 3-D printers on campus, they all follow the same path of creating 3-D objects out of nothing. Unlike subtractive manufacturing, where something is created by reducing something else (Michelangelo created David by starting with a big piece of marble and cutting it down into the shape he wanted), 3-D printing is additive manufacturing. Different additive manufacturing methods exist, such as using molds to create a solid object of something, but 3-D printing is unique in that it creates an object where nothing was before. Bollig and Otto demonstrated just how that works for me by making a small turbine.

The open metal framework of both their machines (Otto’s is a bit larger) houses all the printer’s key components: Gears are set inside the two metal bars that go upward from the base, which raise or lower a metal bar set between them. That bar has a horizontal moving mechanism, which (along with that vertical coordination) brings into position the two nozzles where the actual material to print with will come through. Set above all this, on the printer’s top metal bar, is a holder for the spool that turns out the printing material in a thin, wire-like line (it looks like a thick fishing line coming out). That material is usually a plastic polymer, although St. Thomas students and faculty are researching what different mixes can be used inside different materials (such as putting iron into a polymer so it’s magnetic).

The polymer is fed from the spool down into the top of the nozzle device, which warms it into a liquid that quickly solidifies as it is pushed out onto the flat construction surface. (Nelson-Cheeseman related this process to toothpaste being pushed through the end of the tube onto a toothbrush.) Different polymers have different distinct smells; the PLA (polyactic acid, a biodegradable bioplastic) material Otto and Bollig used to demonstrate for me was sweet, filling the lab with an aroma that wouldn’t have been out of place in a bakery. “Imagine how my dorm room smells all the time,” Otto said.

Once they settled on making a turbine, they connected Otto’s computer and its software, Simplified 3-D, to the printer. The program feeds exact coordinates, programmed in for specific shapes, to the printer instructing where to pour the polymer material to build the turbine. That process happens from the bottom up, layer by layer.

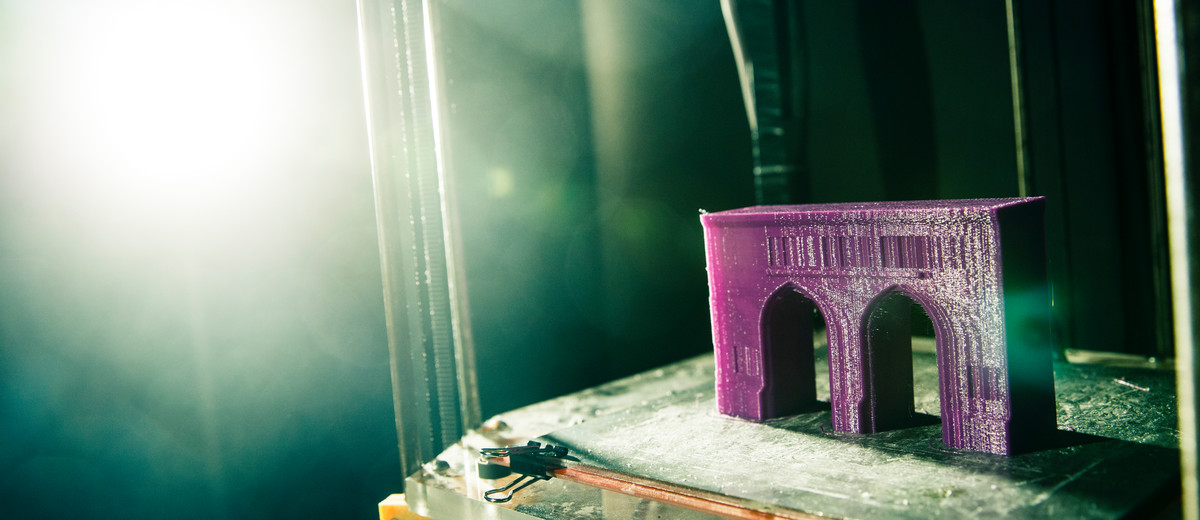

Once Otto began the program, the printer’s gears whirred into action and brought the nozzles (only one was used for this example) down to just above the flat printing surface. It first ran the nozzle in a circular motion and – there on the surface – a green circle of goo-like substance poured into place. Inside that circle it soon began weaving back and forth, pouring out thin layers of polymer in tight lines. Once the entire bottom layer was in place it pulled up a fraction of an inch and began laying down the second layer, criss-crossing with the first.

This played out for the next 90 minutes; the machine slowly put polymer exactly where it needed to be to ultimately shape this small turbine.

Even in the small example, benefits and drawbacks of 3-D printing could be seen: Because the object itself is made in layers, the outside of it reflects that and small ridges can be seen or felt. (Different machines use finer or thicker layers, which can minimize or highlight this effect.) Also, there are only so many different materials you can print with. It can also be a time-consuming process. (Otto pieced together a skateboard of printed pieces that took more than 100 hours to make.)

But, that process can be a lot less time consuming (and less expensive) than other manufacturing processes for many objects, such as prototypes for machine parts. Instead of having to create a mold out of something completely different and then manufacture your part through that, you can make your prototype from scratch. That also opens up a level of customization that is simply not possible with any other kind of manufacturing, because you can make whatever you want within your size and materials constraints. (“Think of it for toy building,” Otto said. “It’s so much more efficient to print an entire toy than to make all the parts and have to assemble them together.”)

The potential of 3-D printing is being realized more and more, and – with students like Otto and Bollig leading the way along with their faculty mentors – the research and work at St. Thomas will continue contributing to this emerging field. It’s really just a matter of what they decide to build next.