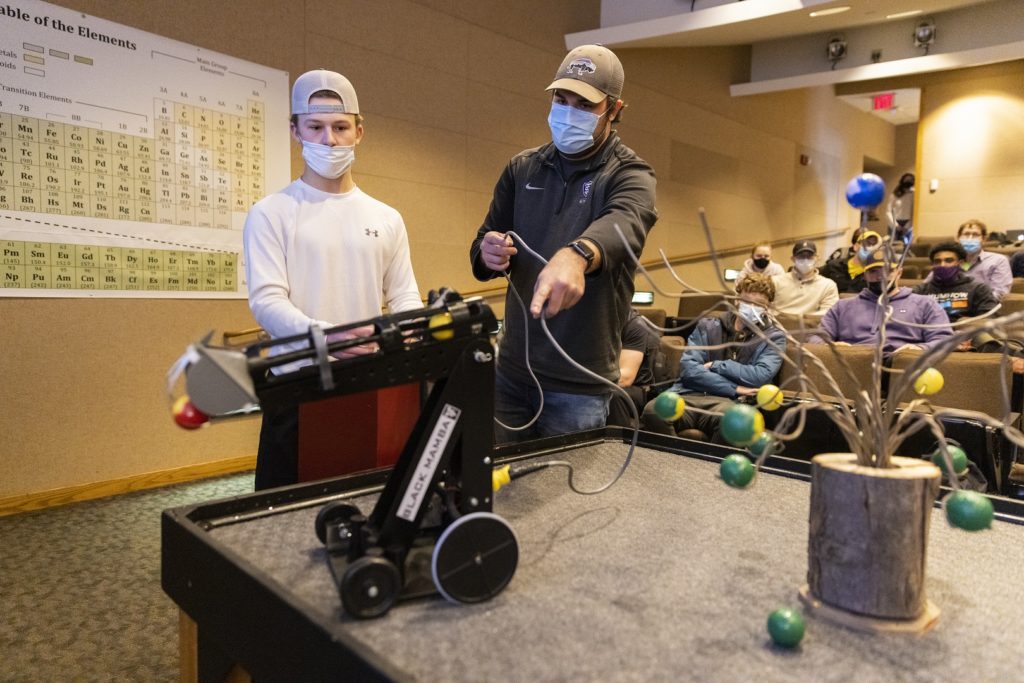

Amid the cheers from the audience and their fellow classmates, students from the Machine Design class steer their robotic machines, trying to harvest as many apples from an orchard tree as possible.

This is the annual School of Engineering Machine Design Challenge. Student teams are given broad customer requirements they must translate into measurable engineering requirements for their machine. In this case, they needed to design a machine that could harvest apples and place them in a bushel as efficiently and quickly as possible. Students also created a 3D computer model of their machines to show how it moves virtually on the computer screen and performs to expectations.

Charlie Eldredge, a junior mechanical engineering student and one half of the winning team, felt the class prepared him to be a real engineer. “Everyone’s first instinct is to get their hands dirty and start building right away, but the class forces you to go slow, be methodical, and actually design your machine as opposed to building blind. Although it was hard at times to do all the background work before getting started on the more fun stuff, it was a great lesson for us all to learn as future engineers,” he said.

The culmination of the project is a single-elimination competition. Students display their machines and enjoy a little competition. Bragging rights this year went to Charlie Eldredge and Jeff Balfany, who is also a junior in mechanical engineering.

“I would attribute our success in the competition to all our hard work throughout the semester,” said Eldredge. “We met frequently outside of class and were both very accountable for getting our parts made on time. By the end of it all, we had five or six different ways of grabbing the ‘apples’ from the tree and I think this is what really helped us succeed in the competition.”